In response to the Government's thrust towards industrial development, especially in economically depressed area of northern Mindanao, a special economic zone was conceived by the proponent in close coordination with the local government units, the concerned line agencies and the private sector in the province.

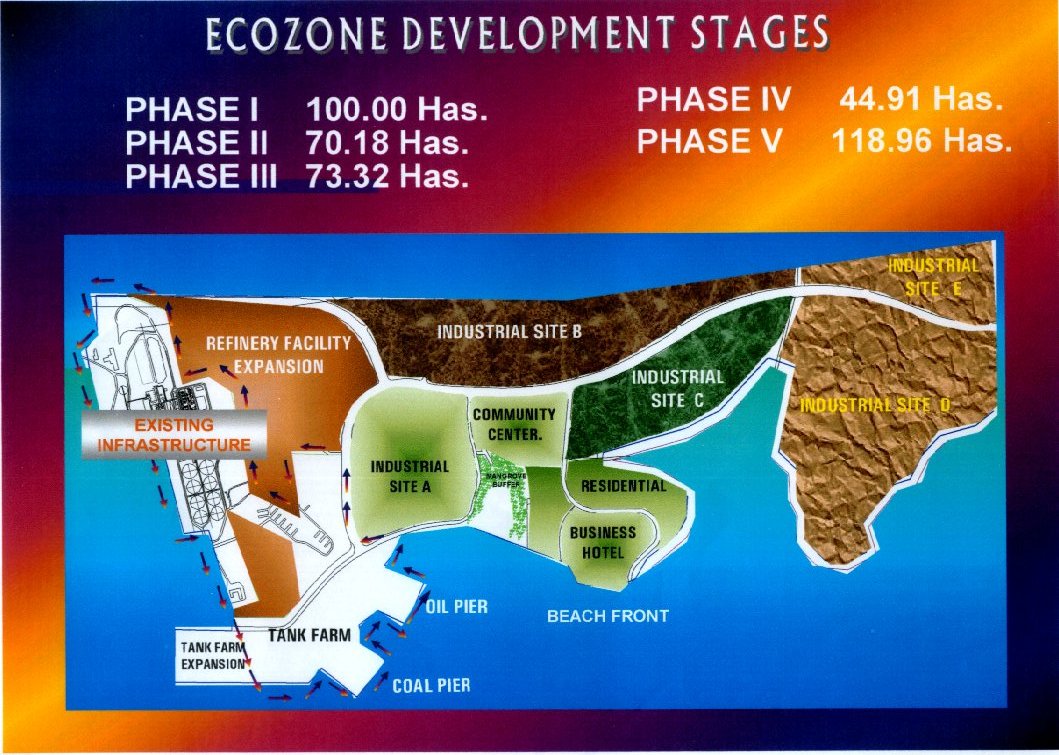

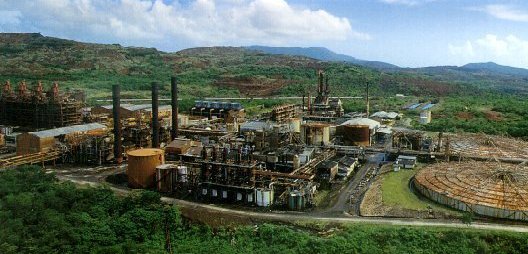

The existence of supporting infrastructure makes the economic zone very viable. A 590-hectare area has been envisaged. Phase I shall cover 100-hectare inclusive of a 60-hectare site occupied by the Nickel Refinery which shall be maintained and operated by Philnico Processing Corporation as the first locator.

In 1996, the project proponent, PHILNICO tasked the SGV to prepare a feasibility

study for the initial 100-hectare Economic Zone development of Nonoc Island.

In April 1997, PHILNICO engaged the services of consultants which led to the

approval on 23 December 1996 by the Board of the Philippine Economic Zone Authority

(PEZA). On October 9, 1999, His Excellency President Joseph Estrada issued

Presidential Proclamation No. 192 creating the Special Economic Zone in Nonoc

Island with an initial area of 106.473 hectares.

The project is in the southern coast of Nonoc Island, within the political jurisdiction of Surigao City, Philippines. Nonoc Island is at bearings 125 degrees 30 minutes East longitude and 9 degrees 50 minutes North Latitude with an average elevation of 39.0 meters above sea level. It is bounded on the North by the Gaboc Channel, on the South by the Hinatuan Passage, on the East by Pacific Ocean, and on the West by Nonoc Bay.

Access to Site

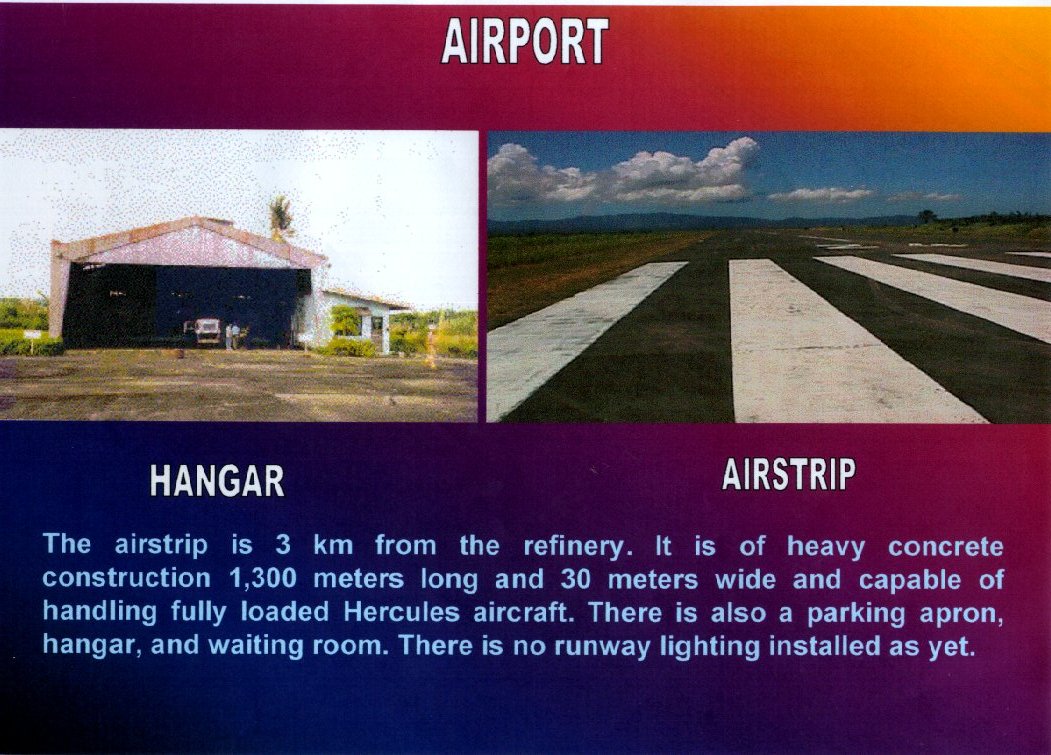

Via Cebu by commercial flights to Surigao

City. High speed ferry also available from Cebu to Surigao City.

From Surigao City's port area, twice daily pumpboats trips are available

to Nonoc Island. Pumpboat trip will take approximately 45 minutes crossing

the Hinatu-an passage stretching approximately 16 kilometers. The island

has an accredited airport to accomodate private planes and chartered flights.

Climate

The climate is governed by three main

air currents: the east-northeast trade winds which occur from February

to May; the northeast monsoon from November to March; and the southwest monsoon

from May to October. The average annual rainfall is about 303.3 mm while

the mean annual temperature is 27.3 degrees Centigrade.

Existing Land Use

Nonoc Island is primarily classified

as a mineral reservation to which Pacific Nickel Philippines has the mineral

rights. It hosts three barangays of Surigao City namely: Nonoc,

Talisay and Cantiasay whose total land area is 50.51 hectares. There are

no defined agricultural land although banana and coconut have been planted by

the locals in quantities sufficient for commercial classification.

Development Concept

First Development The area for the first development measures 106.81 hectares. The nickel refinery, power plant, a pier, a tank farm and a water treatment plant are located in this area. The 20-hectare area beside the refinery may be occupied by four additional locators namely: an oxy-acetylene plant, a drum making plant, lime crushing plant, and a welding electrode plant.

Second Development The remaining 257.87 hectares shall be developed under the second PEZA application. These shall be the building up of industrial plants and other industrial support services needed by the ECOZONE.

ECOZONE Expansion Since the rest of the area are still to be mined, building up of plants shall be done gradually.

Environmental Considerations

An environmental assessment has pinpointed

priority concerns, namely: Drainage Systems, Hazardous Material

Disposal, Groundwater Supply and Contamination, Fugitive Dust, Tailings Dam

Security and Capacity, Solid Waste Disposal and Environmental Damage Control

Methods.

Within the ECOZONE area are the

following existing facilities:

|

|

|

|

|

|

|

|

Aside from PHILNICO Processing Corp., the potential industry locators within the ecozone areas are as follows:

During its more than eleven years of operation,

the Surigao Nickel Refinery had produced and impounded approximately 25

million tons of magnetite tailings in a120-hectare tailings pond.

The tailings contain 40-45 % iron, and because of its magnetic property

can be upgraded to 53-58%. The iron tailings will be an abundant

and cheap material for the manufacture of pig iron and steel.

The nickel refinery will be a captive market for the oxygen/acetylene plant. It is projected that 200 cylinders of oxygen and 100 cylinders will be consumed daily during the rehabilitation of the refinery, and 40 cylinders of oxygen and 20 cylinders of acetylene per day when it starts operation. Other customers will be the other locators. In the absence of a producer, in the area, the locator can serve the oxy-acetylene requirements of the Northeastern Mindanao region.

Nonoc complex has a tank farm with the following facilities:

Tanks Products Capacity

T-201/202/203

Bunker C Fuel

250,000 bbls each

T-103/104

Naptha

105,000 bbls each

T-101

Gasoline

10,000 bbls

T-102

Diesel

10,000 bbls

T-109/110/111/112

Diesel

130 bbls each

T-113

Diesel

250 bbls

T-108

Caustic Soda

1,500 MT

T-106/107

Caustic Acid

1,000 MT each

V-001/002

LPG

80,000 gal. each

The nickel refinery alone will require approximately 450 pieces of steel drums daily to package its products.

With the nickel metal product from the nickel refinery and abundant supply of iron and chromite, from scrap steel or the iron tailings, a stainless steel plant can be established.

The nickel refinery will be scrapping more than 2,000 tons of steel during its reconstruction. This plus the iron from the pig iron plant will be a good source of raw materials. The nickel refinery and other locators will need a variety of replacement parts which can be fabricated by the foundry locator. The locator can export foundry products to the local and international markets.

The nickel refinery management plans to allow the operation of the power an independent power producer (IPP). The nickel plant and prospective locators will be captive market. The excess power may be sold to mainland Mindanao.

The nickel refinery consumes 80-100 tons of ammonia a day for its refining process.

Because of the abundance of chromite deposits in the adjoining Dinagat Island, this plant will be ideal for the site. Sodium dichromate is an essential material for paint manufacturing and leather tanning. Ferrochrome is used to manufacture special needs.

With a cluster of manufacturing plants on site, a common research and development laboratory to serve their needs will be feasible.

The nickel refinery owns a completely-furnished machine shop that can be converted to a metals trade industry. Virtually all machining needs of manufacturing plants and refineries can be served by the shop.

| Home |